It currently has two branches--Shanghai and Dongguan and also has multiple agreement warehouses.

Since its establishment, it has implemented the business philosophy of "Quality wins the market, and integrity creates the brand", and is committed to providing all kinds of tryout material for metal stamping tool shops. Meanwhile, relying on its favorable geographical location, it has achieved considerable development in the industry.

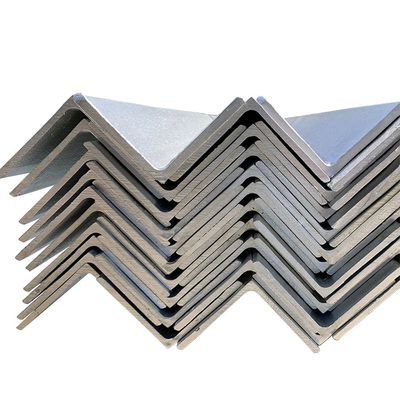

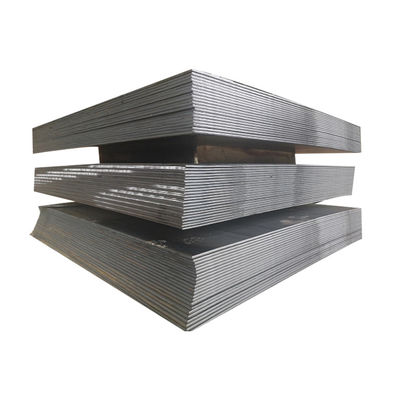

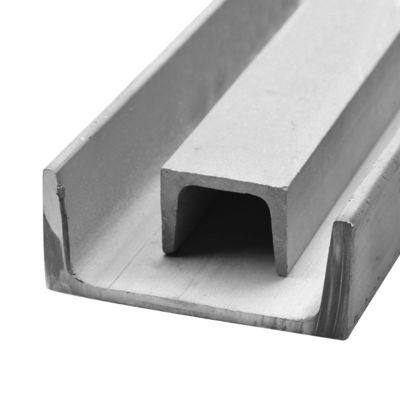

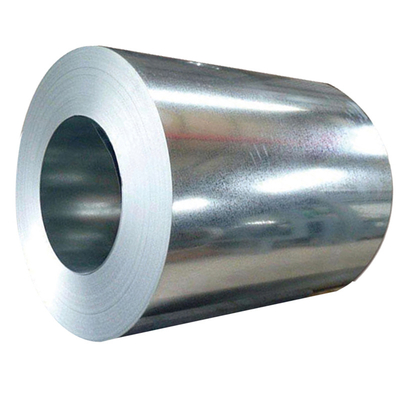

Hanxi mainly services raw material for Automotive white body, including soft and hard steel, Stamping materials, Hardware. The main material comes from Baosteel and can also provide other material for many well-known domestic steel mills like Hot Rolled and Cold-rolled, Pickled, electroplated, electro-galvanized, galvanized, electro-tinned, ZM coated, electrical steel, stainless, aluminum and color-coated coils, etc.

For low volume tryout materials, Hanxi supporting international high standard steel with correct materials.